Hardcover |

Kindle Edition |

Thrilling Incidents In American History |

Perry's Saints |

Prev |

Next

Hardcover |

Kindle Edition |

Thrilling Incidents In American History |

Perry's Saints |

Prev |

Next

The Jet MakersThe Aerospace Industry from 1945 to 1972• Title • Introduction • Preface • Acknowledgements • I: World War II: Aviation Comes of Age • II: The Aerospace Industry since World War II: A Brief History • III: The National Military Strategy: Background for the Government Markets • IV: The Principal Government Market: The United States Air Force • V: The Other Government Markets: The Aerospace Navy, the Air Army, and NASA • VI: Fashions in Government Procurement • VII: The Heartbreak Market: Airliners • VIII: Design or Die: The Supreme Technological Industry • IX: Production: The Payoff • X: Diversification: The Hedge for Survival • XI: Costs: Into the Stratosphere • XII: Finance and Management • XIII: Entry into the Aerospace Industry • XIV: Exit from the Aerospace Industry • XV: The Influence of the Jet Engine on the Industry • Notes • Acronyms • Annotated Bibliography |

VIIIDESIGN OR DIE: THE SUPREME TECHNOLOGICAL INDUSTRYFrom the beginning of the aerospace industry, a high quality of designs has been necessary for full success. This factor has not been sufficient of itself to assure basic corporate success, as the Douglas failure in 1966 showed, nor has lack of it inevitably led to failure. Fairchild has not had a winning major design of its own since the C-119, which ceased production in 1954. How far designs must be pushed to the edge of knowledge is illustrated by the unidentified airframe maker who told a reporter, “The art of aircraft building used to be defined as the art of building things that almost don't work”.1A high proportion of designs are begun with major conceptual flaws, and without final salable designs of its own a company is forced to become a subcontractor. Although this can be a profitable business, it makes the company dependent upon the designs and success of others, and such arrangements mean that the company must please two customers, government and the prime contractor, at the same time; they also shift competitive survival to the production area, where there is less opportunity for competitive advantage. All companies can engage in price competition, but product differentiation is less subject to instant competition, especially if it is based on superior technology. Since under the military procurement system design competition is usually by sole-source negotiation, winning the design competition is the most important business function. It is no coincidence that the major companies have generally been the great designers. Besides being of high quality, winning designs have occasionally resulted from exceptional managerial foresight. Striking examples in which management accurately foresaw a need long before the customer, made extensive preparations, and thereby clinched an advantage include the KC-135/707, Atlas, Minuteman, and Mercury. The one notable breakdown of this advantage was with the F-111, where Boeing's lead in ideas was taken away by McNamara and given to General Dynamics to spur design competition. This factor is especially important when technology is advancing rapidly and there are several technical revolutions at once, as in the fifties. Foresight, even at a less striking level, was more critical after World War II than before. In the thirties the starting point for design, the engine, required little choice of design or flexibility. Only piston engines were practical, in air- or liquid-cooled forms. Technical considerations made even this choice less important than one might think. The Navy and the airlines found distinct advantages to the air-cooled engine because it was lighter. In the United States, only land-based fighters used liquid-cooled engines, and this was because the smaller frontal area meant less total drag and therefore higher speeds. The requirement for propellers limited the possibilities for locating engines in the design. Subsonic flight permitted simple wing and tail designs. ENGINE PROLIFERATIONThe advent of jet propulsion greatly expanded design options and created much uncertainty in choosing the most suitable propulsion or power. At first the piston engine was still competitive, for although it was slightly less powerful it was economical. Its low fuel consumption appealed to the airlines and appeared to be necessary for the ranges the USAF wanted and the take-off and landing requirements of the Navy. A modification of the piston engine appeared in the late forties, the turbo-compound, which combined piston and jet by getting thrust from the piston's exhaust gases. Then there were the simple jet engine and the propjet engine, and the possibility of using both piston and jet engines together-operational aircraft which were such hybrids were the B-36, KB-50, FR, AJ, and P2V. Other possibilities which were not to prove useful were the ramjet and pulse jet engines. At one point in 1952, Douglas was working on airplanes using piston, jet, propjet, and rocket engines. Fewer than one-fourth of the aircraft developed between 1945 and 1958 were completed with the engine models originally planned for them.The designer's dilemma in the circumstances is that often he does not deal with proven, or existing, engines. The justification for a new aircraft is improved performance, and this rests upon better, or future, engines. Thus the designer must select an engine from a shopping list of expectations, and in the immediate post-World War II period the designers found themselves spending as much time in analyzing possible engine-airframe combinations as they had formerly spent in the entire preliminary design of aircraft. For the engines lacking propellers, the designers were faced with new questions of engine locations. Jets could be mounted inside the fuselage, alongside the fuselage, at the tail, inside the wings, under the wings, at the wing tips, or in pods. One of the long-time disadvantages of the twin-engine fighter, that of mounting the engines far from the longitudinal axis, no longer applied because the propeller was no longer required. Over the years, American designers have shown a preference for pod and tail mounts for large aircraft and for internal engine installation along the longitudinal axis for smaller aircraft. At first the Air Force thought the jet was the engine of the future. The Navy believed in the propjet and pushed its development. The Navy thus continued its conservatism; it had kept biplanes as long as it could, then the piston engine, and finally the propeller. Each time one of these had to be abandoned, the difficulty of shipboard operations increased. Because of the success achieved by the Navy in propjet development, the Air Force wavered in its belief in the early fifties. But by the mid-fifties technology settled the issue for years to come. There were large increases in power in the jet engine and small ones in the piston, and the economical by-pass, or fan, jet engine became available; the piston engine was now hopelessly obsolete. The by-pass engine also struck at the main advantage of the propjet: economy. This, plus the inherent propjet disadvantages of propeller limitations and greater engine complexity, mostly in its cantankerous gearing, meant the propjet was badly outclassed. A. contributory jet engine development of the time was thrust augmentation, or afterburning, which provided a great burst of power. Although it was limited to short periods because of its high fuel-consumption rate, afterburning eliminated the need for aircraft rocket engines to provide take-off boost, interceptor climb rates, and dash speeds. By the late fifties the engine proliferation period was over. Since then the jet has reigned supreme as the engine for all but lighter aircraft. In this same period, missiles and space vehicles became important and their best engine is the rocket; only the unmanned aircraft-type guided missiles have not used rocket engines. Of interest to design was the number of engines required. The growing power-to-weight ratio of the jet permitted a reduction in the number of engines at the same time that jet reliability improved the safety factor. From the six-engine B-47 and eight-engine B-52, design has gone to the three-engine L-1011 and DC-10. A reduction in the number of engines simplifies design in general, although two in wing pods and one in the tail may be more complex to design than four in wing pods. An important exception to this trend has been the increasing American use of two-engine fighters. This perverse development is a result of three conditions. First, the American fondness for gadgetry and desire for safety through multiple back-up systems adds weight; the resultant dinosaur needs power so badly that even the powerful modern jets must be mounted in pairs. Second, since the jet engine can be mounted in pairs alongside the horizontal axis, the performance penalty of a two-engine fighter is less conspicuous than in the piston age. Third, it has been argued that the two-engine fighter is safer, an argument which appeals to the top USAF leaders. These officers have been devoted to the big bomber, a multi-engine aircraft in which engine redundancy does add to safety, and their flying careers largely embrace the era of the less reliable piston engine. But the safety argument for a fighter is unacceptable. “Safe” for a wartime fighter means superior performance, and two engines are a handicap for that. Further, having two engines means more weight, a factor which decreases safety even in peacetime, and doubles the probability of failure of one engine as well as the volume of space vulnerable to battle damage. Finally, safety records do not support the intuitive view that two-engine fighters are safer, according to Lockheed, and the conclusion is substantiated by published Air Force figures for what appears to be fiscal year 1968. The service's twin-engine fighters had an accident rate which was 20 percent higher than that of its single-engine fighters.2 Air Force official accident data must be used with caution, however, for some have been influenced by subjective and policy considerations. TRANSONIC AND SUPERSONIC AIRFRAMESWhile the jet expanded the engine options in the early postwar period, it also threw airframe design into turmoil because traditional structures were inadequate at the new high speeds. During World War II the Germans started work on solutions to the design problems of high-speed flight. Their principal answers were to sweep the wings and tail, or to use a delta (triangular-shaped) wing. The American aerospace industry and NASA have refined these successful ideas which have been used on most post-World War II transonic and supersonic aircraft. It should be noted that Americans succeeded in designing an efficient supersonic straight wing. The F-104 has one. In themselves these wing designs have not been enough for the demands of modern flight, however, and the area-rule and variable-sweep designs have also been used.

A General Dynamics FB-111A with wings fully swung for high-speed flight. Courtesy General Dynamics Corporation.

A General Dynamics FB-111A with its variable-sweep wings fully extended for slow-speed flight. Courtesy General Dynamics Corporation.

The best USAAF fighter to see action in World War II was the North American P-51. Designed in a crash effort, the first aircraft (not shown) had many minor engineering faults. Courtesy Rockwell International Corporation.

The first flight of the North American F-86D took place only nine years after that of the P-51. Yet the F-86D absorbed a horrendously greater amount of engineering time than did the P-51. Courtesy Rockwell International Corporation. Aside from assuming the shapes necessary for high-speed flight, structures had to be changed to meet the resultant increased stresses. This problem has been met principally by heavier structures and new materials. The greater lift provided by higher speeds permitted shortening wing spans and deepening chords, making it easier to design strong structures. For the fastest aircraft, complex honeycomb-in-a-sandwich structures have been used for the greatest strength-to-weight relationship. These structural changes have had major impacts on development costs and production processes. Larger, higher-performance, and therefore more expensive test facilities had to be built. The easiest example to cite is the wind tunnels that had to be built to explore supersonic speeds. A comparison of the engineering man-hours taken to first flight for the piston P-51 fighter and for the jet F-86D interceptor shows the trend in design. The figures appear in Table VIII-1, but they must be compared with caution. A fighter is a much simpler machine than an interceptor. The P-51 was designed in haste because the British order for it allowed only 120 days for construction of a prototype. The F-86D was designed at a more leisurely pace. Finally, the F-86D was probably subjected to the costly influences which are discussed below and in Chapter XI. TABLE VIII-1 DESIGN AND ITS EFFECT ON ENGINEERING MAN-HOURS

Before the problems of high-speed flight for aircraft were resolved, designers were called upon to develop ballistic missiles and space vehicles. For the most part these new airframes presented conditions that followed the same development trends as those of the progression to jet from piston aircraft, but they were another seven-league step. THE ELECTRONIC AIRFRAMEConcurrent with the jet age, another technology experienced rapid growth and development: electronics. Possessing great usefulness to aerospace vehicles for communications, navigation, weapons control, and defense against ground-based electronics, electronic devices have multiplied. In the industry they are called avionics. Despite effective miniaturization, they represent much volume and weight in the aggregate, and by 1959 they made up 25 percent of the cost of an aircraft and 35 percent of a missile's. Therefore they present to the designers serious problems in accommodation inside an airframe which has become cramped for space and has desperate overweight tendencies. Like compulsive eaters, the customers find it hard to resist adding attractive items to their wants. In addition, the various avionics systems must be integrated with the airframe and with the vehicle's purpose, a major design problem in itself.THE PROVING OF DESIGNThe problems of design do not end with the assembly of engine, airframe, and avionics into a prototype. A series of critical flight tests must follow, so that the design can be verified in its performance and in its basic safety. Lacking a small margin of performance will make a military aircraft or an airliner obsolete. An unsafe aircraft is unbearably expensive to the military, and is intolerable to the air traveler. Consequently, flight tests are exhaustive for military aircraft and for airliners; the latter's final governmental examination is called certification.Introduction and modification of governmental requirements for airliners have not been simple, for the Civil Aeronautics Administration (CAA), predecessor of the Federal Aviation Agency, had difficulty with the technical details. The manufacturers objected to some of the new rules and expected to have them altered. Some went ahead with designs as they wanted to do them, and then failed to win their arguments. The Boeing Stratocruiser was a victim of this situation as well as of labor troubles; and its tests, certification, and modifications took seventeen months from 1948 to 1949: Boeing blamed the certification tests for much of the company's loss on the airliner. The airliners of this era had manufacturer's flight tests of 300 to 500 hours, and certification tests then brought the totals to 800 to 1,000 hours before carrying passengers. The costs ran up to $7,000 an hour. Despite this procedure airlines had fatal crashes, and the rules were tightened each time. The Comet disasters of 1954 spurred an even more rigorous approach. The Comet affair was still fresh when the Lockheed Electra was put through intensive tests in 1957 and 1958, but even this did not prevent its structural disintegration while in service. Undoubtedly, the Comet also influenced the DC-8's extensive flight tests in 1958 and 1959, which lasted for 2,284 hours. The per hour cost now ranged up to $10,000, and flight tests for the 727 in 1962 and 1963, and for the 737 in 1967, cost $16 million for each. The 747 flight-test plan in 1969 called for 780 hours of manufacturer's tests and 490 hours of certification tests over 11 months, for a cost of $28 million. The tests on the DC-I0 in 1970 cost $26,000 an hour. These costs are obviously a heavy and unavoidable burden in the design and manufacture of airliners. They also provide an insight into the procurement experiments examined in Chapter VI. UNEVEN PROGRESSAerospace technology from 1945 to 1972 has been divided into different periods in several ways above, but another approach should be recognized. Frederic M. Scherer, of the University of Michigan, has divided the technology into three periods based upon its degree of difficulty.3The first period, or generation, had rich possibilities which could be exploited easily, and shortcuts were feasible. This period produced jet bombers, surface-to-air missiles, submarine-launched missiles, satellites, and manned space flight. The second period developed the technologies which had been recognized in the first but had been known to be less easily brought into operation. The hardware in this class was miniaturized nuclear warheads, aircraft capable of Mach 2.2 speeds, more accurate and reliable missiles, and hardened missile silos. Now, Scherer sees a third generation where diminished returns have set in: to get a relatively small increment of improved weaponry, enormous effort must be expended. Scherer, therefore, sees aerospace technology as having advanced with decreasing rapidity since World War II, and as having arrived at a near-plateau. It can also be inferred that a curve of costs would be of an inverse shape for the period. The first revolt against the general progression took place during and after the Korean War. Frustrated by lost victories and dead buddies in combat against the lightweight and nimble MiG-15, USAF fighter pilots mounted a campaign in the Korean War to trim the lard off their obese fighters, which they called “lead sleds.” The effort coincided with concern in Congress over the steeply rising costs of aircraft and with worry over the high quality of the lightweight Russian fighters. The Air Force bowed to the drive, and the F-104 Starfighter was designed under Lockheed's Kelly Johnson to be the fighter pilot's dream airplane. Light, designed for easy production and therefore maintenance, and with superb performance, the Starfighter was an excellent fighter. It did not go all the way to lightness, for Johnson believed some of the stripping desired by the fighter pilots was not justified by the performance gained. But it reversed the trend of rising costs, for its price was half that of the contemporary heavy, sluggish F-100. By the time the F-104 was ready for production in 1956 the fighter pilot campaign had lost its momentum, war memories were fading rapidly, and only token amounts were. bought by the USAF. Instead, the Air Council returned to buying expensive “fighters” that had bomber characteristics, such as the elephantine F-105, the “Thud.” The F-104 was produced in quantity, but only for our allies. A third group contributed to the general revolt of the early fifties against runaway weight and cost. These were designers, and their most outspoken member was E. H. Heinemann, chief engineer at Douglas' El Segundo plant. Heinemann's accomplishments included three excellent piston attack planes: the A-20, the A-26, and the A-I. Heinemann insisted that insufficient attention was paid to eliminating needless equipment, and that this was the main villain in the weight-cost spiral.4 He contended that equipment added resulted in a multiplier effect of ten times in the gross weight, although other estimates ranged down to seven. Thus, an excess crew member, with man and his equipment weighing 200 pounds, meant aircraft gross weight would jump 2,000 pounds to accommodate him, because of necessary structural modifications and additions in fuel. Two thousand pounds adds a critical burden to fighters and attack aircraft as well as to design and production costs. Heinemann got a chance to practice what he preached. In the Navy's jet reequipping program a replacement was sought for his A-I. An earlier attempt had been made with the propjet A2D, but its engine's technical problems were never mastered. Meeting Navy specifications for the new plane without weight-saving efforts meant an appalling weight of 45,000 pounds. But Heinemann produced a masterpiece, the 1954 A-4, which weighed less than 10,000 pounds empty and 17,000 pounds loaded. It had only one-third the number of structural parts of earlier Douglas attack designs. For example, a skin one-tenth of an inch thick was used at the cockpit, eliminating stiffeners and thereby reducing aircraft size, as well as greatly facilitating production. A favorite with the Navy, the A-4 has been called “Heinemann's Hot Rod.” It was a workhorse aircraft in Vietnam and was still in production after nineteen years.

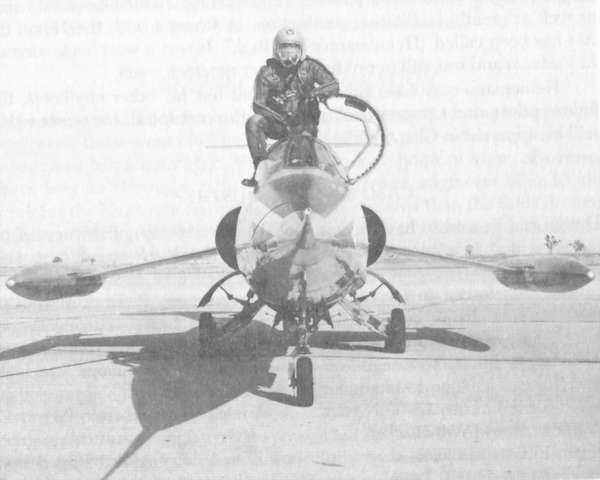

The fighter pilot's fighter plane: performance with simplicity. The Lockheed F-I04 with Lockheed test pilot Tony LeVier. Courtesy Lockheed Aircraft Corporation.

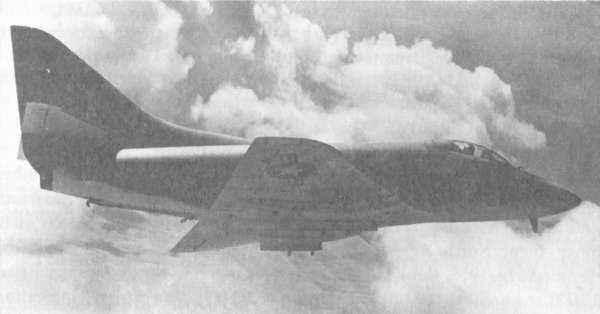

An American classic, the McDonnell Douglas A-4 shows the virtues of simple design. Courtesy McDonnell Douglas Corporation. Heinemann may have proved his point but he, other engineers, the fighter pilots, and Congress did not arrest the cost spiral, for reasons that will be apparent in Chapter XI. CAMPUS OR INDUSTRY?Design can be said to have been a major growth section of the aerospace industry, if it is interpreted to include research, development, test, and evaluation (RDT&E). When newly created, the USAF, lacking an arsenal system, was forced to turn to industry for weapons R&D. Universities were far from being ignored, however, and they were soon devoting a heavy share of their capacity to defense research. The aerospace industry itself began faintly to resemble a research campus with shops attached. And this was a major development for that industry, which had previously relied for the most part on NACA. NACA itself switched from its quickfix role in World War II when the reports on German aeronautical progress began to How in. From then until Sputnik in 1957, NACA plunged into supersonic research. Notable was the development of the area-rule and variable-sweep wings. The advent of space flight meant a massive reorientation by the reorganized agency, now NASA, into primarily space R&D.But the postwar situation was concurrent R&D by both NACA/NASA and the aerospace industry. The industry's participation in research coincided with the great technological revolutions of the period after World War II, and that part of the aerospace business which does RDT&E for the Defense Departn1ent grew tenfold from $758 million in 1951 to almost $7.75 billion in 1967. One of the giant companies, North American, evolved so that its business was primarily in this area although its airplane production has continued, and there has been production of other hardware such as rocket engines and avionics. In 1961 North American had 22,000 scientists and engineers out of a workforce of 88,000 men. Since then, North American's proportion of scientists and engineers declined. In 1966, the last year before its merger, North American had 16,000 researchers out of a workforce of 92,000. An extreme indication of the role of R&D in design is the report that North American put 15 million engineering man-hours into the XB- 70, and this was only to first flight. Thousands of engineers have been used on some projects: 2,600 on the B-58, 2,500 on the C-141, and 3,600 on Minuteman. ENGINEER PROLIFERATIONOver the years, as the aerospace companies recruited these armies of engineers, there were often cries of a “shortage,” and much publicity has been given to such an idea. From an economic point of view, of course, there was no shortage; rather, there were fewer engineers who would work for the aerospace companies at the pay offered than the firms desired to have. During the “shortage” there was a steady stream of engineers' letters to the editor of Aviation Week-and there were too many for too long to be written by a few cranks-which asserted that engineers in the aerospace industry were underused and subjected to mismanagement by personnel officers and management. A study of 1956, repeated in 1959, appeared to confirm this.5

Besides the study and the persistent

letter-writing, there are other indications that engineer requirements of the

aerospace industry should have been lower. In 1971 A. Scheffer Lang of MIT said

of the defense companies, “Their engineering approach relies heavily on dollar

overkill as the way to solve problems.”6 Kelly Johnson of Lockheed had an

ordinary engineering department of 5,000 men in 1956. He found that only 5

percent of their time was spent on making hardware.7 The brilliant

Floyd Odlum

The most telling criticism of massed-manpower engineering practices is

the record of the “Skunk Works.”

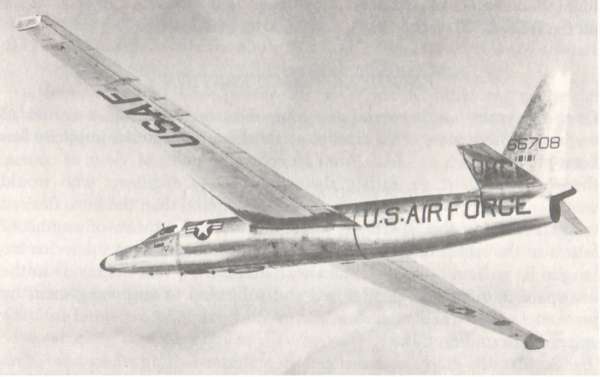

The famous Lockheed U-2, another development triumph of the Skunk Works. Courtesy Lockheed Aircraft Corporation. Even American airliner design practices must be suspect. Since the airlines have not accepted substandard equipment, have paid for enormous overruns, have been willing to wait, and have been most price conscious, one would expect the use of engineers on airliner design to be economic. However, it must be acknowledged that airliner competition is between “equals” in one sense: none of the American companies are in a strictly civilian market. They are all veterans of the military aircraft business, and therefore they lack the skill of firms in the civilian market to hold down costs. One thousand engineers were used to design both the Electra and the 727, despite the circumstance that the 727 used as many existing 707 and 720 parts as possible. The 747 used 2,500 engineers, and the L-1011, 1,500. The Electra grossed 113,000 pounds; the 727, 170,000 pounds; the 747, 713,000 pounds; and the L-1011, 430,000 pounds. Discounting the existence of some ability to transfer airliner costs to military contracts, called “migration,” the record on airliners still contrasts sharply with the record of Lockheed's special unit. Perhaps a better comparison would be with the French Avions Marcel Dassault company, a shrewd and aggressive firm which produces top-notch designs at low prices. Its Mirage fighter was the basic equipment with which Israel smashed the Arab forces in the war of 1967. Dassault uses a Kelly Johnson style of development. To produce its Mirage IV, a 77,000 pound (gross weight) supersonic strategic bomber comparable to the F-111, Dassault used fewer than 85 engineers and draftsmen for development. From design approval to first flight took only eleven months. Producing such a bomber should be a problem of at least the same engineering magnitude as a jetliner. One can only conclude that ingrained traditional methods, including a carry-over from military contracts, account for the American use of masses of engineers, even on airliners.  Design engineers at work at Lockheed. Courtesy Lockheed Aircraft Corporation. |